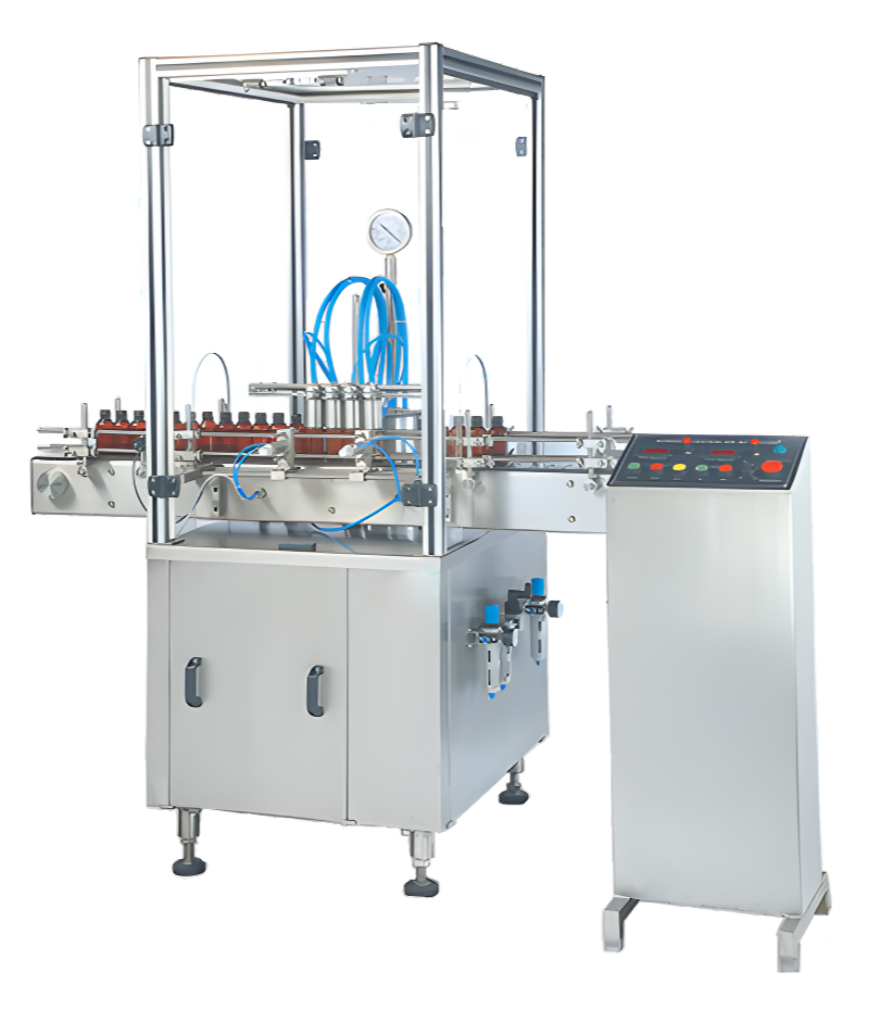

Automatic Airjet Cleaning Machine is compact and highly efficient machine with elegant look. This multi featured machine meets the GMP requirements of clean glass and plastic bottles & Jars for non-sterile products like Dry Syrup, Bulk Packing for Tablets & Capsules etc. and found a method of cleaning each individual Bottle/Jar by air jet & vacuum. All contact parts are made from Stainless Steel 316L, or FDA approved materials for GMP compliance. Bottle vacuum cleaning machine works on a principle of back pressure of Bottle which fed by the unscramble to reach separator assembly, which transfer the Bottle on conveyor belt and pushes bottle to the cleaning section one after another. Cleaning section is equipped with continuous vacuum system. Bottle reaches to the cleaning section, a pair of nozzle starts to flush the air inside the neck of the Bottle and simultaneously vacuum will suck the particle, disturbed by the air. Duly cleaned bottles further transfer onto exit end of conveyor and transfers bottles onto another machine or outfeed collection tray. The Airjet Cleaning Machine applies compressed air through jets and also sucks through vacuum. Machine can be used to clean Glass/Plastic/Pet Bottles, Jars etc. Machine is suitable for cleaning of non-sterile products like Dry Syrups and Bulk Packing of Tablets & Capsules. Machine with Built with Turn Table which feeds container in vertical position through conveyor to cleaning station, where cleaning heads grip the container through cup holder and starts the compressed air and then vacuum to clean the bottles. Machine finished with stainless steel finish & all contact parts in SS 316 and nylon materials, also having overload clutch system to prevent jamming during the operation. The manifold comprises of inner nozzles which jets compressed air in the bottle and an outer socket, which cover the mouth of the bottle and is connected to an exhaust, ensures perfect cleaning.